Back in the late 1950s, the sound of unmuffled diesel engines that powered Caterpillar’s D8 tractors of that era could be heard on earthmoving projects around the world. This article explores the similarities and differences between the D8 14A (Series E and F) and 15A (Series D and G) tractors that were produced between 1955 and 1958.

A Brief History of the D8

Back in the 1930s, earthmoving machines were brute force and power. As decades passed, these thunderous diesels gave way to quieter, computer-controlled engines and strong arm levers gave way to power-assist controls. Back then, Caterpillar's biggest crawler tractor was the Diesel Seventy-Five, which was replaced by the RD8 in 1935. The first RD8’s were known as the 5E Series and only 35 of these machines were produced. Later that same year, the RD8-1H Series was introduced, which featured Caterpillar’s new D13000 diesel engine that produced 110 flywheel horsepower and a six-speed forward, two-speed reverse transmission.

The “R” prefix was dropped in 1937 and the “D8” was born. Caterpillar produced just under 8,000 1H Series tractors before the Second World War came along. To meet wartime demands, Caterpillar introduced the 130 horsepower 8R Series machine and around 9,900 of these tractors were produced between 1941 and 1945.

Anticipating a boom in construction activity following World War 2, Caterpillar began working on design changes for the D8 and in 1944; these were incorporated in the 2U Series, which was officially released in mid-1945. Upgrades included a power boost to 148 horsepower, a new 5-speed constant mesh transmission featuring a forward and reverse lever (better known as a Johnson bar), a two-position front idler (which was a great asset in scraper work), an enclosed clutch on tractors beginning with Serial Number 2U12283 and an oil clutch on tractors starting at Serial Number 2U21513. The oil clutch extended plate life and helped to cool the clutch, which was often subjected to heavy loads. Production of the 2U lasted until 1953 with over 27,000 tractors being manufactured during this period. It should be noted that two “sub-variants” of the 2U were also produced - the “Pusher” and the “Hi-Output” versions.

The final D8 to use Caterpillar’s D13000 engine was the 13A Series, introduced in 1953. Engine output was increased to 185 flywheel horsepower and the 13A retained the 5-speed transmission and oil clutch of the previous 2U Series machines. The 13A also featured a larger “L-shaped” fuel tank and single operators’ seat (replacing the former bench seat of previous versions). Only 3,510 of these tractors were manufactured between 1953 and 1955 when it was replaced by the all-new D8 Series D (15A) and D8 Series E (14A) machines.

The initial 14As (with Serial Numbers 14A1 to 14A3861) were known as Series E and were produced in 1955 and 1956. From Serial Number 3862 and up, they became the Series F, produced from 1956 to 1958. The initial 15As (with Serial Numbers 15A1 to 15A1673) were known as Series D machines and were made in 1955 and 1956. Tractors with Serial Numbers starting at 15A1674 became known as the Series G and were produced from 1956 to 1958.

The 15A was a highly valued machine for push-loading scrapers. Its torque converter drive was the key, as it was for the Allis-Chalmers HD-19 crawler. As the engine lugged down, this power transmission device would multiply engine torque to provide a smooth transition of power from the engine to the tracks, which allowed the operator to travel further into the cut when push-loading scrapers without having to de-clutch and gear down like he would with a direct drive machine. This is why the 15A only needed a three-speed transmission rather than the five-speed used on direct drive (14A) machines because the torque converter did most of the torque multiplication.

Differences between the 14A &15A

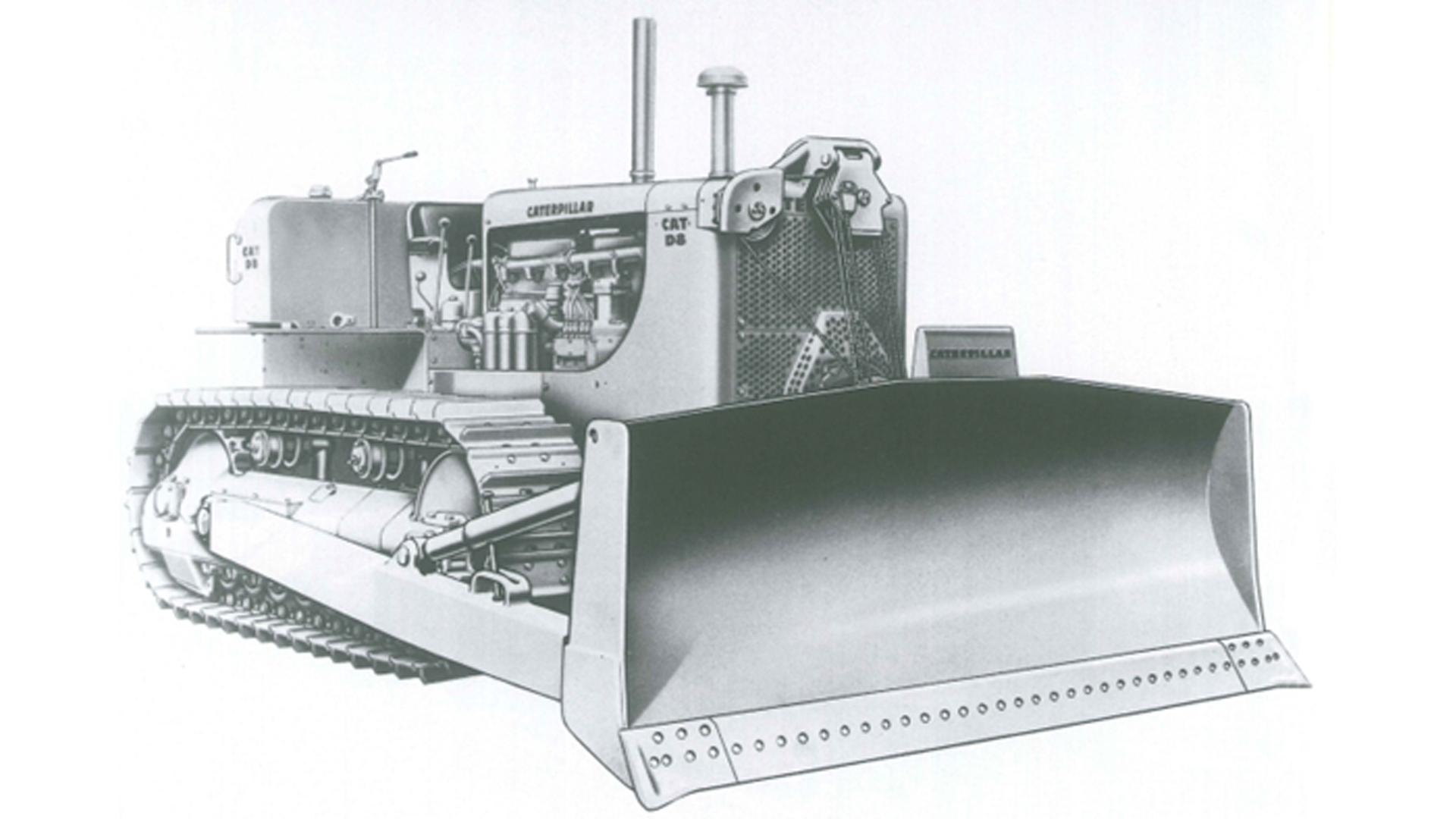

The 14A was a direct drive machine, which means that it has a clutch mounted on the flywheel that drives directly into the transmission. This machine featured a 5-speed constant mesh transmission with filtered full pressure lubrication. It also featured a 3-plate oil-cooled clutch. With an operating weight of 41,535 lbs. and a length of 16'-3½", it sold for US $24,795 when introduced.

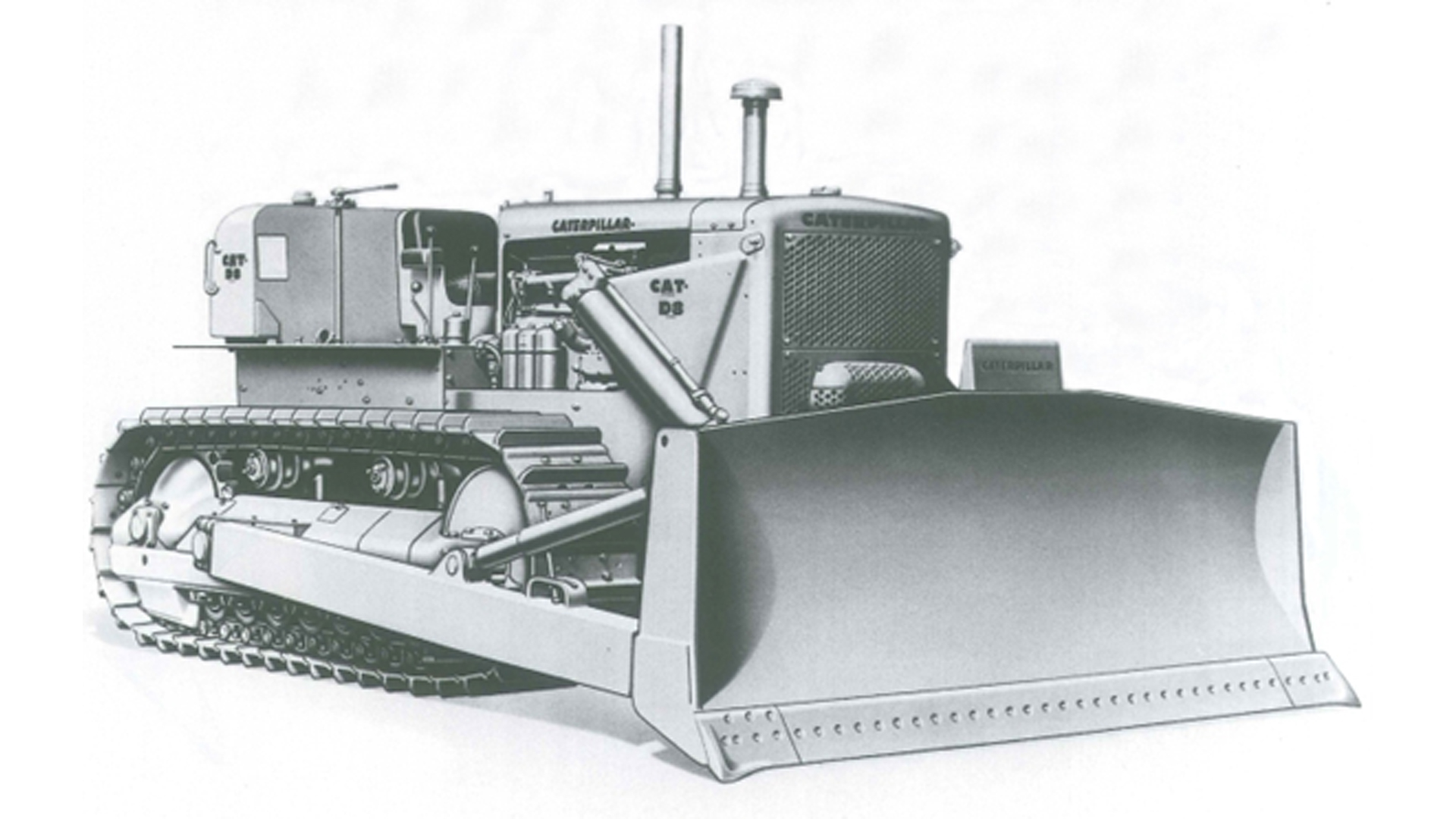

The 15A was a torque converter machine that featured a single-plate dry clutch mounted to the flywheel, which drove a 3-stage torque converter. From the torque converter, power went into the transmission. The torque converter was charged with pressurized fuel from the fuel tank similar to the Allis-Chalmers HD-19 and International TD-24 machines. The transmission was 3-speed constant mesh with filtered full pressure lubrication. Length of the machine was 17'-2", 8½ inches longer than the 14A. It sold for $27,200 US in 1955 and its operating weight was 42,480 lbs.

Features of the 14A &15A

Both machines featured single reduction final drives. An interesting note here is that when these machines were first introduced, they were experiencing final drive failures, particularly in western Canada. Caterpillar dealers began noticing that faces of the bull gears and pinions were pitting and gears were breaking. Later, it was discovered that the increase in horsepower and the use of angle blades (commonly used in forestry road construction in the mountains of British Columbia) caused the axle the bull gear rides on to deflect, which caused improper gear to tooth contact and thus gear failure. Caterpillar then made a stronger gear and other improvements to correct the problem and advised owners to regularly adjust final drive bearings and change the oil on a regular basis.

Torque converters on the early 15A machines were also a weak point but this was soon corrected and that problem went away as well.

Early models of both machines had dry type brakes and steering clutches until Serial Numbers 14A03861 and 15A01673. All models after these serial numbers (after 1956) had oil-cooled steering clutches and brakes, which extended service life and improved operating characteristics. In addition, each steel plate on the oil-cooled steering clutch was deliberately warped 0.009 of an inch in seven places to break the oil film when the clutch was released so the discs had no viscous drag.

Another interesting feature was hydraulically boosted controls on the steering clutch release mechanism. This greatly reduced operator fatigue and was a better system than the old spring-boosted steering clutch release mechanisms of the older model D8 tractors.

The 14A’s and 15A’s were the first Caterpillar crawlers to have hydraulic track adjusters, making track adjustment so much easier. The Serial Number of these machines were 14A03500 and up (for the Series E and F machines) and 15A01503 and up for the Series D and G machines. With this improvement, the operator only needed a grease gun to adjust the tracks rather than a big wrench and possibly a torch to loosen the big adjuster nut on the older model tractors.

Attachments

Three bulldozers were available - the 8A (angle blade), 8S (straight blade) and the 8U (universal blade). In addition to these more common blades, various specialized attachments were also available like a push cup that could be fitted to the C-frame of the 8A blade or a push plate that hung on an 8S blade to protect it when push-loading scrapers. Caterpillar offered both cable- and hydraulically-controlled blades. Cable control units included the rear-mounted No. 29 (which was driven by a live shaft from the transmission) and the front-mounted No. 30. The No. 46 hydraulic control was driven off the front of the crankshaft and was favored by less experienced operators who were not used to the quick-response cable controls. The No. 29 cable control was not well-suited to the 15A because of slippage in the torque converter. When under heavy blade load or when loading towed scrapers, the converter would slip, resulting in varying revolutions per minute to the cable control unit. This caused erratic operation of the blade or scraper. According to the 1958 Performance Handbook, the wire rope speed on the No. 29 CCU was slightly lower for the 15A than for the 14A.

Two towing winches were available for both tractors - the Hyster D8D and the Carco winch. The Hyster was more popular because it just bolted onto the tractor whereas the Carco winch required special adapters and modifications for mounting.

A one-, two- or three-shank ripper was offered as well. The No. 8 tractor-mounted ripper was operated by the No. 48 hydraulic control, which actuated ripper functions. The shank angle could be adjusted by removing the top pin and moving the shank forward or backward to adjust the tooth angle to best penetrate the type of material to be ripped. The shank was also mounted in a bracket pinned to the ripper beam, which allowed the shank to move sideways about ten degrees to let it swing around immovable objects. This ripper was known as a hinge-type ripper.

Conclusions

The 14A and 15A tractors stayed at 191 horsepower up to the time they were replaced by the improved, more powerful turbocharged 35A, 36A and 46A machines. All in all, the 14A and 15A tractors gave good service to their owners and some are still in operation today. As the 90th anniversary of the introduction of the D8 approaches without special recognition, this model is still in action today, although the 21st Century machines are much heavier and more powerful than the 8R Series introduced in 1935. These machines have worked around the globe on many projects, both large and small; and always, they get the job done.

For those of you who have an interest in D8s, there is a Facebook page called "Shaping the World with the Caterpillar D8".

An early model RD8 bulldozer preparing a logging road in the bush

April, 1955 advertisement introducing the “New D8”

D8 14A tractor with 8S blade and No. 30 cable control

D8 14A tractor with 8S blade and No. 46 hydraulic control

D8 14A with root rake and ripper clearing a highway right-of-way

D8 14A with 8A blade and No. 29 cable control opening a channel

D8 14A loading a No. 80 towed scraper

D8 14A with 8S cable-operated blade and hydraulic tilt cylinder

D8 15A with 8U blade and No. 29 cable control stockpiling material at Brownsville, PA

D8 15A with 8A blade and No. 29 rear-mounted cable control pushing fill

D8 14A with Hyster winch hauling logs to load-out

D8 15A with 8S blade and No. 30 cable control excavates foundation for a power plant extension