Within Benjamin Holt’s prolific list of tractor designs, one seminal machine would solidly cement his genius with track type machines creating a benchmark tractor that would be sought all over the world even to this day, his Model 75 “Caterpillar”. This breakthrough innovation would quickly become the world’s gold standard, revolutionizing the concept of utility from a tractor while transforming the way things would be done in the future using full mechanical advantage.

Two major beneficiaries of this marvel would be the farming and construction industries. It is interesting to note that by and large, to this day, agricultural and construction equipment typically function in disparate worlds. Modern heavy agricultural tractors cannot be dedicated to and survive the punishment doled out by the rugged demands of the construction realm without heavy modifications or near complete re-designs. Manufacturer’s are still learning that expensive lesson over 100 years later. Going back to Mr. Holt’s Model 75 that first appeared in 1913 we find a machine that would excel in both realms without modification. The 75 would do so; so well that it would be propelled into new roles. This time into the mechanized war party where it would change things by global orders of magnitude. This trine of success would make Mr. Holt one of the most preeminent pioneers of the craft.

Previous to this iconic Model 75, Benjamin had almost a decade of successful continuous tracked crawler machines that would become trademarked as “Caterpillars”. These early machines would typically feature tiller wheel assisted steering and tracks for lower ground pressure and terrain crossing capabilities. This setup was already proven in the western United States first by its steam powered predecessors and gasoline models such as the Holt 45 and Holt 60. At the time of its introduction, The Holt 75 would be the second most powerful of the line of tractors Holt was offering. Weighing in at nearly 11.5 tons, the Holt 75 was powered by a giant 22.9 liter/1,397 cubic-inch displacement gasoline motor. With 7.5” diameter pistons traveling an 8” stroke, the model 75 produced 75 brake horsepower and delivered 50 horsepower at the drawbar allowing a towing capacity in excess of 5 tons and an exhilarating slugfest top speed of 3 miles per hour (in solo/unladen form). The Holt 75 quickly became renowned by farmers for its universal Swiss pocket knife-like utility with its factory “belt pulley” auxiliary drive option. The belt pulley could be used to power electrical generators acting as a power plant, or to drive pumps and threshers, etc. As a tractor, effective deep or large-scale plowing and pulling large combines was typically all done with ease.

It was not long before Holt Caterpillar tractors captured significant attention from international governments and militaries. In 1914 as quickly as it had appeared on the world stage, the Holt 75 would be thrust into trials and was subsequently ordered in vast numbers by war departments of the United States, Britain and Russia upon the outbreak of World War I. It should also be noted that prior to the war’s beginning, from 1912-1914, around 150 Holt Caterpillar tractors of various models were exported to Hungary and Austria, which would later be pressed into service with the German Army, the bulk of which were the venerable 75’s.

Known to Allied militaries as the Holt “15 Ton” artillery tractor, the Model 75 would quickly replace the horse and wagon as the logistical backbone of the war effort, pulling howitzers in excess of the 6-inch shell diameter and general supply wagons with great success. On the heels of Great Britain’s entry to the Great War, a career British officer would find himself taking direct inspiration from his introduction to the Holt 75 that would completely revolutionize warfare up until the modern age.

Peoria Military Holt 75 in service with the Canadian Army pulling artillery, note the artillery is transported in pieces, Western Front.

Major General Ernest Swinton, by and large recognized as the “Father of the Tank” played a significant part in developing and adopting the world’s first tanks into military service on behalf of the United Kingdom.The idea to weaponize a tracked type vehicle first came to Swinton in late 1914 after reflecting on a letter he received earlier in the year by an associate, a Mr. Hugh F. Marriott, a mining engineer detailing an American machine - a Holt 75 he’d seen on trial, explaining the tractor’s terrain crossing capabilities and suggesting it may be useful for transportation. Without delay, Swinton would inspire Winston Churchill to form the “Landship Committee” in February of 1915. This began efforts to develop an armed and armored machine based on the Caterpillar system to storm over battlefields and punch through enemy lines. The significance of this project required secrecy so it was given the codename of “tank” from the term “water tanks”. The first Mark I Landships would see combat at the Somme in September of 1916. Shortly after British successes with their first tanks, Germany would develop and deploy their own. The Germans would use actual re-purposed Holt chassis components from the tractors that had been imported into Europe prior to the war as the basis for their A7V assault tanks but these efforts proved unsuccessful. In any event, tanks were largely responsible for ending the years long stalemate in trench warfare, and In February 1918, General Swinton travelled to Stockton, California to personally thank Benjamin Holt and company for thei manufacture of the Caterpillar tractors the allies used in the war. According to the Holt Mfg. Company’s official wartime production numbers publication, approximately 1,810 Model 75 Caterpillar tractors were produced for the Allied war effort, with the motors being manufactured in Stockton, CA and tractors being produced in Peoria, IL.

Benjamin Holt (left) pictured with Gen. Ernest Swinton pictured with Stockton Holt 75 No.3307 and Holt H.A. 36 Tank Prototype. Stockton, California, 1918. Photo Credit: The Holt Brothers by Jack Alexander

An interesting anecdote to the development of the military version of the Holt 75 is that bar starting flutes would be eliminated from the flywheels with bar starting itself being replaced with a hand pulled flywheel adaptation. This was a countermeasure employed to prevent soldiers from conveniently improvising the use of their not so expendable/bendable rifle barrels in place of starting bars that could get lost.

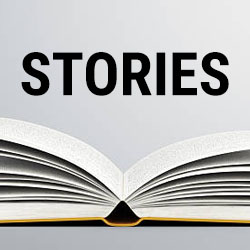

Excellent side-rear view of a Peoria Military Holt 75, note the protective shrouding over the steering clutches, drive assembly, and main clutch. Fluteless starting flywheel is also visible.

Concurrent to the Great War, another military expedition was conducted also utilizing the Holt 75 to its fullest ability during the Mexican revolution. In March 1916 General John J. Pershing, led the command of U.S. Expeditionary forces in pursuit of Pancho Villa that would march deep into Mexico supported by a fleet of Holt 75’s. As across the pond in Europe, Holt 75’s were widely deployed for transporting artillery, ordinance and general provisions in support of the US expeditionary forces. After this military endeavor General Pershing wrote that the expedition would’ve been impossible without the aid of Truck and Tractor, paying homage to the Holt machines which accompanied his forces nearly 500 miles south of the US-Mexico border.

Stockton Holt 75 Tractor No. 2467, used by Gen. Pershing’s Expeditionary forces during the Pancho Villa Expedition, Mexico, 1916.

After the Armistice ending WWI in November 1918, many Holt 75’s were either shipped back to the US or remained in Europe and returned to farm and civil work over both shores. Returned wartime 75’s were sold off to the American public as surplus for half the price of new tractors, with the consequence of crippling Holt Mfg. company’s annual sales. This development led Holt to begin pursuing domestic civil infrastructure opportunities, mostly consisting of road building and construction. Adding more unease to Holt’s outlook, by the end of WWI, the Holt 75 was facing obsolescence against competitor brands. Most notably, C.L. Best’s Model A Sixty Tracklayer was introduced in 1919. Nonetheless, Holt and its 75’s weren’t going away. Both new and surplus Holt 75’s were put to work across the country pulling levelers and pull type graders. It was in this application that one man’s ingenuity, pairing with a Holt 75 and land leveler, which would evolve the way humanity moved earth for generations, especially after the ripples caused by the next player of mention, Mr. Robert G. LeTourneau.

Born in 1888 to a farming family in Richmond Vermont, LeTourneau would move multiple times throughout his childhood, and dropped out of Highschool to become an Ironworker’s apprentice in Portland, Oregon. Throughout his early adult life he worked within a wide variety of trades, exposing him to invaluable technologies and skill sets. Most notable of these capabilities was arc welding, which would later prove to be pivotal to his budding trajectory as an iconic innovator and business leader. After World War I, LeTourneau directed his interest into the earthmoving business as the Holt Caterpillars took the industry by storm. As his start-up, Mr. LeTourneau purchased a Holt 75, rented a land leveler and hired an operator, establishing himself as a land leveling contractor. LeTourneau’s business was very successful, but also

costly as he had an extra man required to operate the tow behind leveler to take care of. At this time in 1920s America, labor costs were very high, land leveling teams also needed to be fed and housed on large projects. LeTourneau quickly began devising ways to eliminate the need for 2-man operating teams to increase his efficiency.

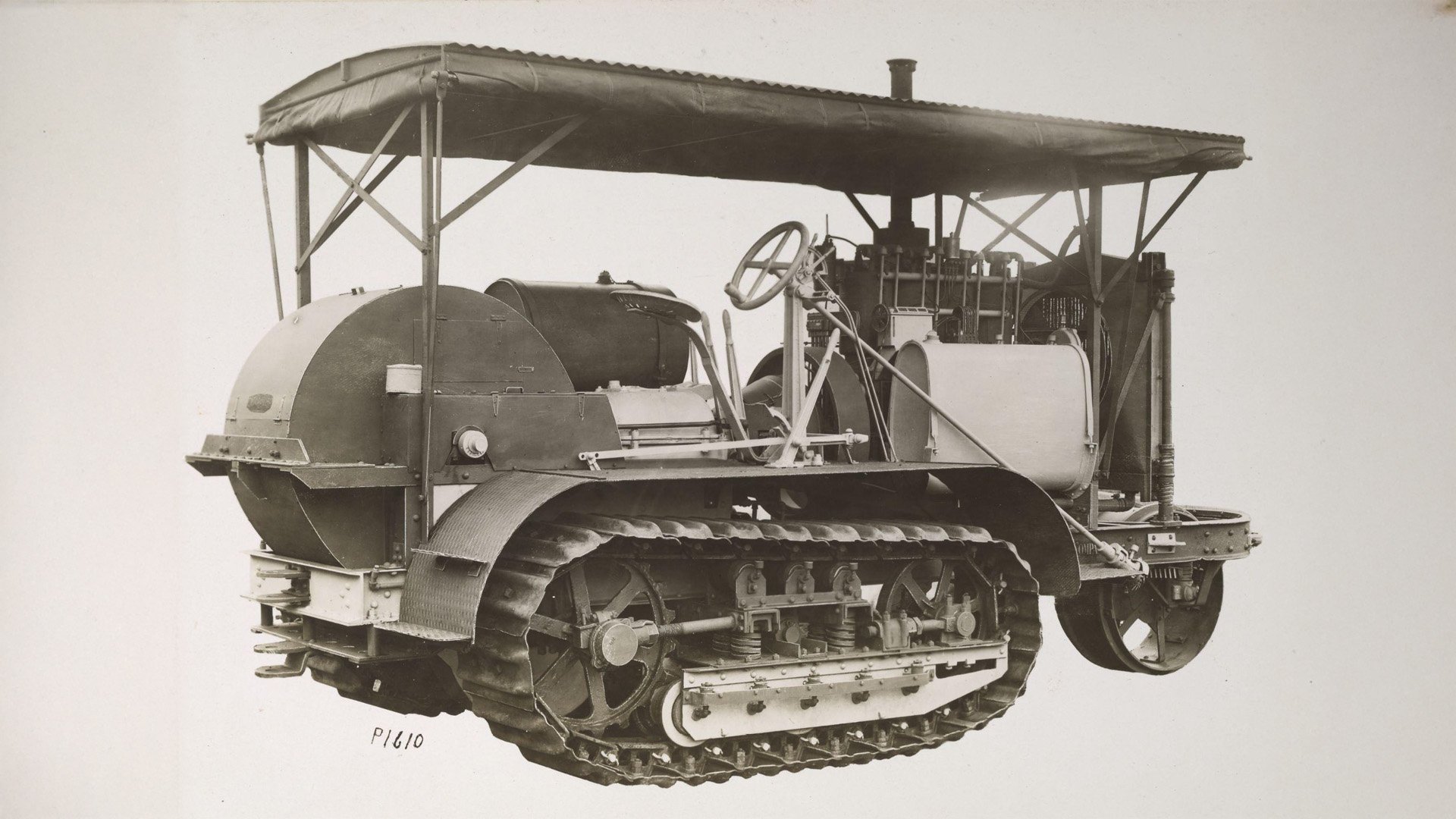

LeTourneau put his single operator enabled leveler ideas to work in 1921. To accomplish this, he would mount generators on the rear of his Holt 75 tractor to run electric motors with cabling and pulley systems all to be controlled by a single operator that could both drive and manipulate land leveler functions (colloquially referred to as scrapers). His experiment was a major success cascading into the floodgates of innovation opening up for the construction world. LeTourneau went on to develop his own drag scrapers and introduced welded construction over riveting to heavy equipment manufacturing which was truly revolutionary. LeTourneau writes very extensively about this period of his life in his autobiography, “Mover of Men and Mountains” and is an incredible read for any fan of construction and equipment history.

R.G. LeTourneau in the seat of his Stockton Holt 75 pulling his first one man operated “Full-Drag” scraper, 1921. Note “R.G. LeTourneau” vaguely visible on the front of the 75’s canopy. Photo Credit: R.G. LeTourneau Heavy Equipment: The Mechanical Drive Era 1921-1953, by Eric C. Orlemann

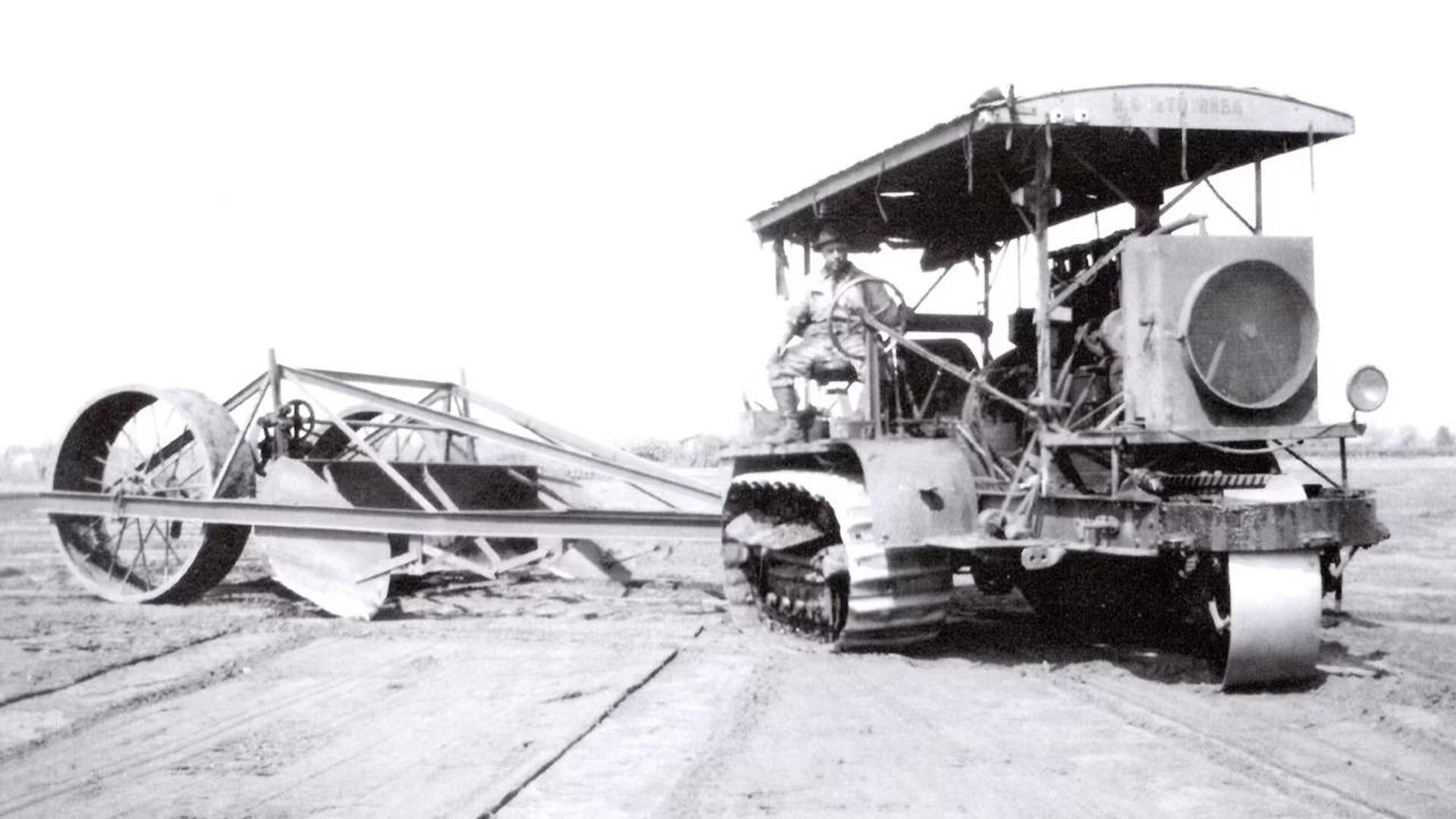

Alongside LeTourneau’s invention in 1921, The Stockton division of the Holt Mfg. Company upgraded and released their final iteration of the Holt 75, commonly known today as the “Late Stockton 75”. The Late Stockton featured an all-new cast-iron radiator, motor changes such as enclosed rocker arms, pushrods and most notably fully locking/steering brakes for both tracks, rather than just friction clutches. By this time the Holt 75 was relegated mostly to limited agricultural work, struggling against the modern engineering that C.L. Best had introduced in his Model A Sixty Tracklayer, which was conquering the west coast’s farming industry. Reportedly only 67 of these Late Stockon Holt 75s were ever produced from 1921 to 1924 (S.N. 4001-4057, gap 4068-4077), marking the end of the Holt 75, just a decade after its introduction.

Late Stockton Holt 75 (T-80) No. 4001, 1921. Photo credit: The Caterpillar’s Roots by Jack Alexander

Over 100 years later, the Holt 75 remains an unmistakable icon of construction and Agricultural history. Prized by many collectors and museums, many Holt 75’s remain in operating condition today, and make appearances at tractor related events all over the world. I grew up alongside one particular 1917 Stockton Holt 75, owned by collector Josh Stephenson from Temecula, CA, seeing it run often at annual shows put on by the Antique Gas and Steam Museum in Vista, CA. I was finally able to operate a WWI veteran Peoria Holt 75 from the courtesy of Tom Madden and the volunteers at the Best of The West show in Santa Margarita, CA. Not being one to lie, it was a very rugged/kinetic hands-on experience to manage, but also an operating experience I will never forget and one I find myself craving over and over.

Josh Stephenson and his 1917 Stockon Holt 75 No. 2938 on parade at the Antique Gas & Steam Museum in Vista, CA, 2017. Photo Credit: Neil Paku

Finally, I find it difficult to tire from burying myself in staring at and appreciating the countless details forming the embodiment of Holt 75’s. The entire machine was very purposefully designed over every surface and nuance for strength and material use efficiency. The drive sprockets for example have an oddly modern look to them. They almost appear to have been designed with modern 3D engineering software to provide the minimal mass required but maximum strength with a given amount of material while retaining an artistic fluidity. There are many graceful elements adding a fine degree of elegance far beyond mere utility. They truly are a bespoke work of art and reflect very far forward-looking sensibilities and aesthetics for their day. The shape and form of their stamped tracks and intricacies of the radiators are simply marvelous to behold.

Eyewitness by Ernest Swinton

The Caterpillar’s Roots by Jack Alexander

The Holt Brothers by Jack Alexander

Classic Caterpillar Crawlers by Eric C. Orlemann